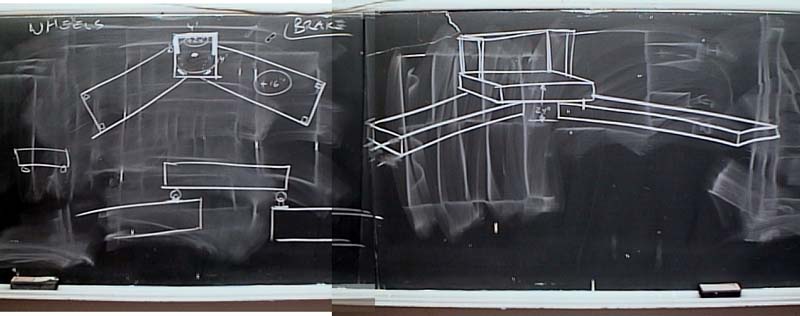

Here’s a mix-n-match set of platform methods. The open framed part is called a parallel.The platforms on the top are comprised of a basic 4×8 and a 4×4 platform framed using 1×6 lumber. The bottom platforms are only slightly different as they are framed with 2×6 lumber. These bottom platforms also have casters attached. Remember the question that was asked during class. How do we make this 4’x4′ platform rotate? It is sitting on top of the two 4’x8′ platforms that do not provide a solid, complete surface.

In other words, where do the wheels go?

More questions to think about:

- What is the elevation of each level of platforming?

- What is the height of the caster we’re using?

- Do we use straight or swivel casters?

- How do we get the platform to rotate and not go where ever it wants to?

- How do we stop it from rotating? (Lock it in place)

- How do we get it to turn?

A curved platform is pretty easy to build. The curved front is cut from a single piece of plywood. the framing members were cut from the scrap that was created. The front is covered with a thin plywood that is bent, gently. The top was then covered with a sheet of ply and the front edge was trimmed.